How Industrial Scales Improve Efficiency in Manufacturing and Warehousing

Wiki Article

All Regarding Industrial Scales: Trick Functions and Benefits for Your Work Environment

Industrial scales are essential in enhancing operational performance across numerous industries, supplying features such as high capability, precision accuracy, and durable building and construction. These instruments not only decrease human error however additionally assist in data integration and regulative conformity, making them vital for high quality control and product monitoring. As companies progressively identify the significance of these devices, the effects for performance and waste decrease become significantly substantial. Comprehending the diverse types and applications of commercial ranges can supply beneficial understandings right into optimizing your workplace processes-- yet, the journey doesn't finish there.Kinds of Industrial Scales

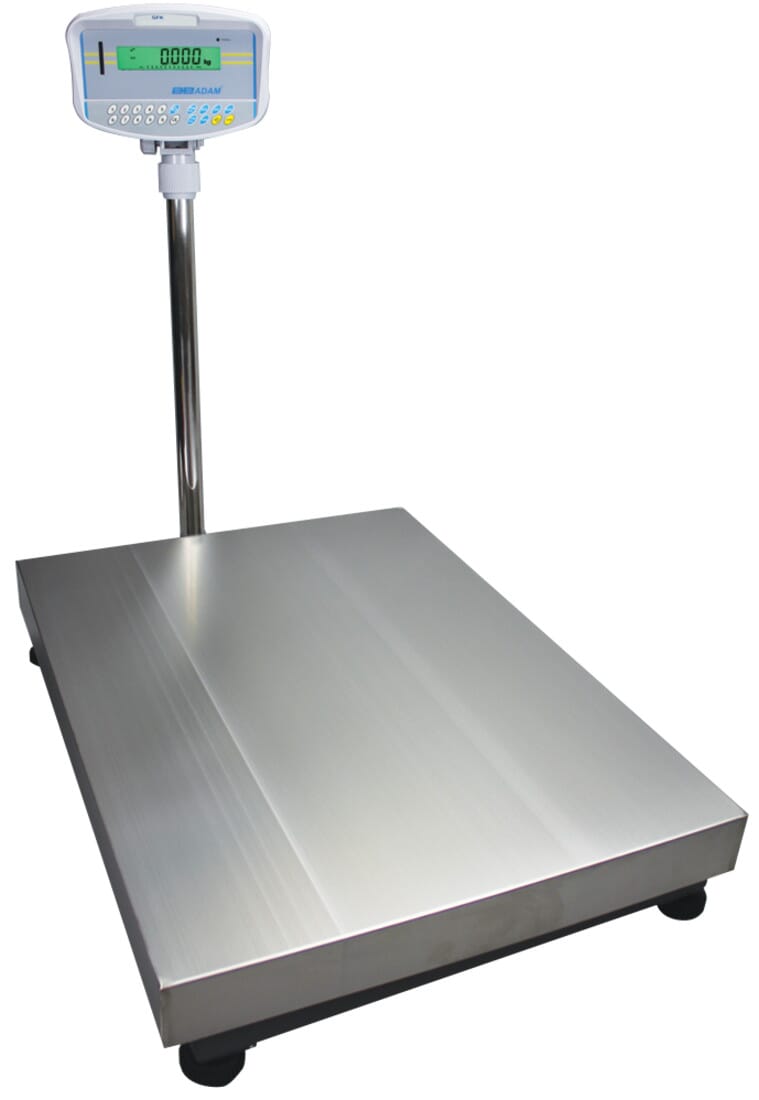

Industrial scales are important tools used across various industries for precise weight measurement. They come in several kinds, each created to accommodate certain applications and atmospheres. One typical type is the system range, which supplies a large weighing surface area ideal for bulky and hefty products. These scales are often utilized in warehouses and delivery facilities.An additional common type is the bench range, which is suitable and portable for smaller things. These scales are regularly found in retail and food solution settings, where quick and specific measurements are essential. Floor ranges serve a comparable purpose yet are designed for durable applications, allowing for the evaluating of large pallets and containers directly on the ground.

Moreover, digital ranges have gotten appeal because of their convenience of use and precision. They frequently include advanced electronics that enhance capability, such as connectivity choices for information tracking. Furthermore, mobile scales provide adaptability for on-the-go weighing, making them very useful in fields like farming and logistics.

Recognizing the various sorts of commercial ranges is vital for picking the appropriate equipment to meet specific functional demands, making sure performance and accuracy in weight measurement.

Secret Functions of Industrial Scales

When picking the suitable type of commercial range, it is necessary to think about the crucial attributes that enhance their performance and viability for certain applications. Among one of the most important features is the scale's capability. Industrial ranges are offered in various weight capacities, guaranteeing that they can fit the demands of different markets, from light materials to heavy loads.Another essential feature is accuracy. High-precision tons cells are essential for guaranteeing that dimensions are reputable and constant, which is important for inventory management and quality assurance. Additionally, the readability of the display plays a substantial duty; clear, digital screens with adjustable brightness permit for simple viewing in various lighting problems.

Toughness is another key particular, with lots of industrial ranges designed to stand up to rough environments, consisting of direct exposure to wetness, chemicals, and hefty use. Some models even include waterproof or stainless-steel construction. Furthermore, connectivity options such as Bluetooth or USB make it possible for seamless information transfer and integration with various other systems.

Benefits for Workplace Performance

In addition, commercial ranges allow faster processing times. With automated weighing solutions, employees can rapidly acquire weight why not find out more information without hands-on computations, freeing up time for other important jobs. This velocity in process not only boosts functional effectiveness but also aids satisfy production deadlines a lot more successfully.

Furthermore, industrial ranges offer valuable information that can be examined for continuous renovation. By checking weight patterns, companies can identify ineffectiveness in their processes and implement restorative actions, inevitably leading to boosted performance.

The assimilation of these scales additionally sustains compliance with industry policies, as precise reporting of weights is frequently called for. This decreases the threat of expensive penalties and improves the firm's track record for reliability. Industrial Scales. Generally, the incorporation of commercial scales adds to a more reliable, cost-effective, and certified office environment

Applications in Numerous Industries

In the food market, commercial scales are utilized for part control, dish formulation, and conformity with wellness laws, assuring food safety and security and uniformity. In the pharmaceutical market, precise evaluating is important for drug solution, where even minor disparities can lead to substantial regulative concerns and safety and security concerns.

Building and logistics markets additionally gain from commercial scales, as they aid in maximizing and handling raw materials delivery processes. By providing exact weight data, these ranges assist in better lots planning and conformity with transport laws.

Additionally, the agricultural sector utilizes industrial ranges for weighing livestock, feed, and fruit and vegetables, thus boosting operational efficiency and making sure fair profession techniques.

Maintenance and Calibration Tips

To ensure ideal efficiency and longevity of commercial ranges, regular upkeep and calibration are vital. A consistent upkeep timetable helps determine possible issues before they rise, therefore minimizing downtime and repair service prices. Operators should regularly cleanse the scale to stop particles accumulation, which can impact precision (Industrial Scales). Furthermore, inspecting the load cells, electrical wiring, and display screen for wear or damages is important.Calibration is similarly essential; it makes sure that the scale provides exact analyses in conformity with sector requirements. It is suggested to calibrate scales frequently-- at the very least annually or even more often if the scale is used heavily or relocated frequently. Follow the supplier's standards for calibration treatments, which typically consist of making use of certified calibration weights.

Additionally, keeping proper ecological problems, such as temperature level and moisture control, can improve scale performance and accuracy. Last but not least, educating team on correct usage methods will even more protect against abuse that might result in inaccuracies or damage. By sticking to these maintenance and calibration suggestions, businesses can guarantee their industrial scales run efficiently, eventually supporting performance and conformity with regulatory criteria.

Final Thought

In recap, industrial scales offer as vital tools for enhancing ergonomics across diverse industries (Industrial Scales). Their high capability, precision accuracy, and durable building and construction add to ideal procedures and high quality visit site control. The integration of sophisticated features, such as digital screens and information connectivity, additionally minimizes human mistake and sustains regulative conformity. By understanding the essential attributes and benefits of commercial scales, organizations can utilize these tools to enhance product use, reduce waste, and eventually drive performance.Industrial ranges are pivotal in improving operational effectiveness throughout numerous industries, providing functions such as high ability, precision accuracy, and durable construction.When selecting the proper kind of commercial range, it is vital to consider the key features that boost their functionality and suitability for specific applications. By offering accurate weight measurements, industrial ranges remove the possibility for human mistake, ensuring that products are considered continually and specifically. It is advisable to adjust ranges frequently-- at least once a year or even more regularly if the range is utilized heavily or moved frequently. By recognizing the vital attributes and benefits of industrial scales, companies can utilize these devices to boost product use, minimize waste, and eventually drive productivity.

Report this wiki page